- Home

- About Us

- Solution

- Recruitment

-

Contact Us

Contact Us

- Shopping Cart

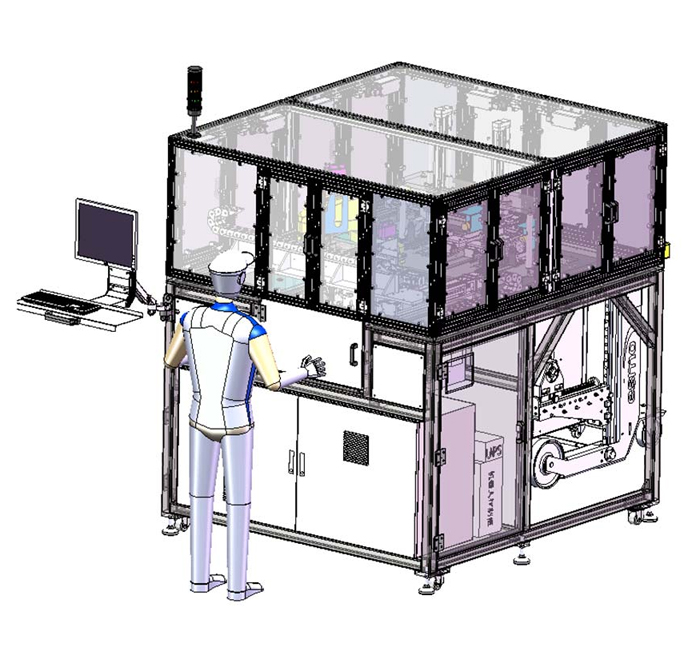

Machine Features/机器特征

1. Support automatic loading and unloading of tray to tray. 支持Tray to Tray自动化上下料

2. Cooperate with test machine to support automatic chip delivery to test locationAnd complete the test, the whole operation process does not produce any impact on the chipdamage 与测试机配合支持自动化运送芯片到测试位置 并完成测试,整个运作过程不对芯片产生任何 损伤

3. The two‐dimensional code of the tray can be read and the data can be corresponding to the trayStorage and storage 可读取Tray盘二维码,并对数据进行Tray对应 和储存

4. Bus motion control system. 总线运动控制系统

5. Support GPIB and TCP / IP communication mode, with at least twoGPIB interface and TCP / IP interface 支持GPIB和TCP/IP通信方式,至少配有两个 GPIB接口和TCP/IP接口 IGBT Test Solution 裸芯片测试分选机 ITS

6. Intelligent Controls: (1)Programmable parameters ,TFT LCD touch screen. (2)Self‐diagnosis for trouble shooting. (3)Fault detection for strip handing, feeding, orientation and alignment. (4)Machine management information system. 智能型控制系统: (1)系统参数可由触摸屏设定。 (2)故障检测可视化。 (3)故障报警模块化。 (4)机器管理资讯系统。

7. After the reserved chip is tested, the optical inspection function of the whole chip is performedIdentify the space of scratch, crack and other defects, which is convenient for later equipment upgrade 预留芯片测试后对整个芯片进行光学检能 识别出划伤,Crack等缺陷的空间,便于后 期设备升级

■ Key Function / 主要规格

The static and dynamic test sorting of the cut bare chip is realized by the bare chip test sorting machine cooperating with the testing machine. The size of bare chip is 5x5mm ~ 20x20mm, the thickness range of chip is 65um‐150um, the tolerance of overall dimension is less than + / ‐ 0.01mm, and the tolerance of thickness is less than + / ‐ 5um. Space is reserved for checking the appearance of chip for scratch and other defects after test, which is used for equipment upgrading.

裸芯片测试分选机配合测试机实现切割后裸芯片的静态和动态测试的分选。支持裸芯片的尺寸 5x5mm~20x20mm,芯片厚度范围65um-150um, 外形尺寸公差小于+/-0.01mm,厚度公差小于+/- 5um, 预留测试后还对芯片的外观进行检查是否有划伤等缺陷的空间,用于设备升级改造。

■ Specification / 规格

Size / 尺寸: 1850mm (L) x 1700mm (W) x 2000mm (H)

Weight / 重量: 3000 kg

Power Source / 电源: 3ψ+E AC380V 50HZ

Power Consumption / 消耗电源: 50KVA

Air Pressure / 气压: 4 ~ 6 Bars

Control System / 控制系统: OMRON CJ Series

Man Machine Interface / 人机界面: Pro‐face touch screen

Applicable Electrode Specs/ 适用电极规格: Thickness/厚度: 65um-150um Length/长度:5~20mm With/宽度:5~20mm

Production Capacity/ 设备产能: 4pcs/min